| Concrete Manhole | Plastic Manhole |

|

More than half of the concrete manholes, start to leak soon after the installation. Concrete manholes, become thinner and fragile eventually with the effect of groundwater and chemicals. Crack formations lead to leaks. These cracks with bringing along the corrosions prepare the grounds for manhole collapses that frequently seen. Moreover, small deformations that may be found in the connections of the moisture they contain as a result of leakage, cause corrosion and prevent communication. |

It is highly resistant against water and chemicals. It protects environment with its tightness feature. Leakage is minimal thanks to its profile design, plastic material and cable entry equipment's. Moreover, it prevents the attachments from being by moisture as it does not pass the moisture in the soil into itself. |

| Concrete Manhole | Plastic Manhole |

|

Plastic pipes and concrete manholes cannot be attached without any leakage. |

Plastic pipes are attached to plastic manholes in a way that completely prevents leakage. |

| Concrete Manhole | Plastic Manhole |

|

It can be damaged in the areas that subject to intense vibration and natural earth movements. Concrete manholes, often cause problems in the regions where the air temperature is very low and frosts are very common. Frost cracks and collapses can be especially seen at the parts that bear the shutter. |

Plastic manholes, can absorb the pulses without any damage thanks to their flexibility and modular structure compared to concrete ones. Furthermore, plastic manholes are not affected by air temperature or frost. |

| Concrete Manhole | Plastic Manhole |

|

Heavy equipment needed for transportation and installation with its 1400 kg weight. During the transportation and asambleof concrete manholes, breaks and cracks occur. The concrete manholes, that assembledas cracked by the neglectful field forces, cause collapse in the future. |

Thanks to its modular structure, parts can be reduced to the sizes one person can carry without any difficulty. In total it is 15% of the weight compared to the concrete manholes at the same sizes. |

| Concrete Manhole | Plastic Manhole |

|

Minimum 4 employees, a truck, 1 Crane and Crane operator should be sent to the field in bulk shipments during the installation. It is essential that employees at the field should be educated in order not to harm manholes. The limited mobility of the heavy vehicles such as cranes, sometimes can make the installation impossible especially at the field works. The assembly time takes approximately 5-6 hours excluding shipment and incorrect operations. All of these items are the highest cost items among the cost of concrete manholes analysis. |

It can be easily assembled with 2 employees. There is not any possibility of incorrect assembly thanks to its design. Therefore, there is no need of technical stuff. It can be assembled with light equipment's. Since there is no need for any operations such as screwing, cutting, fixation in the field, there occurs no problems about lack of material, at the field. It is very easily shipped and applied for the difficult conditions and field works. The assembly time takes approximately 20 minutes excluding shipment and incorrect operations. These advantages of plastic manholes provide in operational cost, ensure that their price remain below the concrete manholes. |

| Concrete Manhole | Plastic Manhole |

|

It should be loaded by crane from factory. Heavy vehicles must be used for transportation. Crane must be used during lowering. Lowering and assembly should be made very cautiously in case of any crack or break. Crane should be used again in case of ground faults or other problems to remove it. |

Installation done manually. It can be shipped to the field at the desired time by any kind of shipment vehicles. Since there is no risk of damage such as cracking, breakage, there is no need to be sensitive at the field. It can be disassembled in minutes in case of ground faults or other problems. |

| Concrete Manhole | Plastic Manhole |

|

Concrete does not have any standard lifespan as its interaction with soil and the corrosion of its reinforcement by constant exposure to moisture. For these reasons, can be damaged in a short time. This problem tried to be eliminated by covering the inner Wall of the concrete manholes, overseas. Insulation can be done at the damaged areas, hence it is obligated to controlperiodically. |

The lifespan of the plastic manholes underground is very long. The average lifespan considered as 50 years due to the earth movements. It does not require any maintenance throughout its existence. |

| Concrete Manhole | Plastic Manhole |

|

Under the condition, without leakage taken into account, the greenhouse emission is 33kg/year, if added 423kg/year CO2. |

Greenhouse gas emission is 2kg/year CO2. |

| Concrete Manhole | Plastic Manhole |

|

It can be considered as inexpensive on the first purchase. However, costs increase due to the assembly, short life-span and maintenance difficulty. |

Although, it seems expensive on the first purchase, it provides price advantage with its superior features in the long term. |

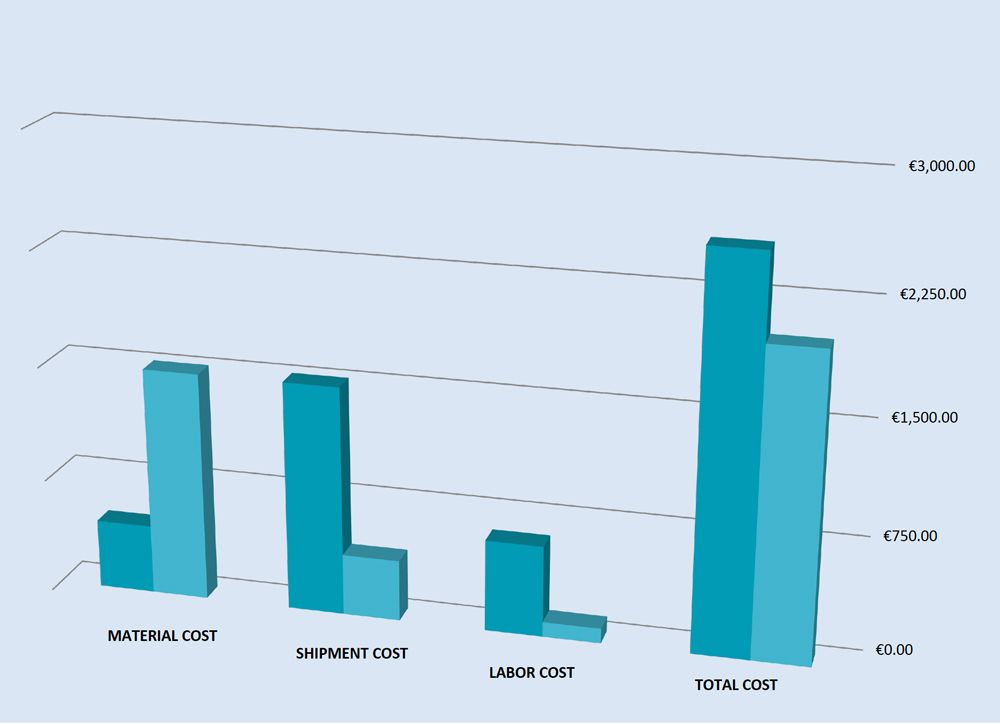

Cost Analysis

Comparison Chart of Manhole Costs